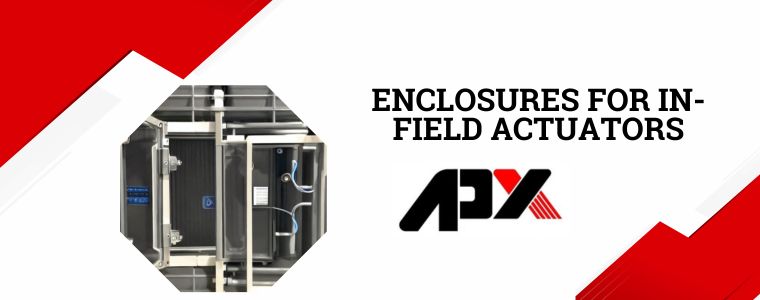

In-field actuators play a crucial role in a wide range of industries, from manufacturing and agriculture to energy and automation. These actuators are designed to control and manipulate various machinery and equipment, ensuring precise movements and efficient operations. However, to ensure the optimal performance and longevity of in-field actuators, the selection of suitable enclosures becomes imperative. Enclosures for in-field actuators provide protection against environmental factors such as dust, moisture, extreme temperatures, and corrosive substances. Moreover, they contribute to the overall reliability and safety of the actuator system. This article delves into the importance of enclosures for in-field actuators, factors to consider in enclosure selection, different types of enclosures available, design considerations, installation and maintenance practices and future trends in actuator enclosures. By understanding the significance and best practices of enclosures, businesses can enhance the performance and durability of their in-field actuators while ensuring the safety of their operations.

1. Introduction to In-Field Actuators

1.1 What are In-Field Actuators?

In-field actuators are like the unsung heroes of the industrial world. They are tiny devices that make big things happen. These nifty contraptions are responsible for converting electrical energy into mechanical motion, powering everything from valves and pumps to doors and gates. Without them, our modern world would come to a grinding halt, quite literally.

1.2 Applications of In-Field Actuators

In-field actuators are the workhorses in a wide range of industries. You can find them bustling away in manufacturing plants, water treatment facilities, oil and gas refineries, and even in our homes, quietly doing their job. They are the key players in automating processes, controlling fluid flow, and giving life to countless machines and devices. From opening and closing valves to adjusting flow rates, these little powerhouses do it all.

2. Importance of Enclosures for Actuators

2.1 Protecting Actuators from Environmental Factors

Actuators might be tough, but they aren’t invincible. Just like humans, they need protection from the elements. Dust, dirt, water, extreme temperatures, and even pesky critters can wreak havoc on their delicate mechanisms. That’s where enclosures come to the rescue. Enclosures shield actuators from the harsh outside world, ensuring they keep functioning optimally for years to come.

2.2 Ensuring Reliability and Longevity

An unprotected actuator is like a ticking time bomb waiting to go off. Exposure to environmental factors can lead to corrosion, electrical shorts, and general wear and tear, decreasing reliability and shortening its lifespan. Enclosures provide a safe haven, extending the longevity of actuators and reducing the need for frequent repairs or replacements. It’s like giving your actuator a cozy little home with a do-not-disturb sign.

3. Factors to Consider in Enclosure Selection

3.1 Environmental Conditions and Exposure

When choosing an enclosure for your beloved actuator, think about where it will be stationed. Is it going to be outdoors, being battered by wind and rain? Or is it going to be inside a cozy factory, away from the elements? Consider the environmental conditions and exposure your actuator will face to ensure you select an enclosure that can handle the heat (or cold), so to speak.

3.2 Size and Configuration of Actuator

Size matters, and this rings true for actuator enclosures too. You need an enclosure that fits your actuator like a glove, providing snug protection without squeezing the life out of it. Consider the dimensions and configuration of your actuator when selecting an enclosure, ensuring a match made in heaven. We don’t want any awkward enclosures that leave actuators feeling cramped and restricted.

3.3 Material Selection for Enclosures

Choosing the right material for your actuator enclosure is like deciding on the perfect outfit for a night out. It should be sturdy yet lightweight, resistant to corrosion, and able to withstand the test of time. Common enclosure materials include stainless steel, aluminum, and polycarbonate, each with its own set of pros and cons. Pick the material that best suits your actuator’s needs.

4. Types of Enclosures for In-Field Actuators

4.1 Weatherproof Enclosures

Remember how your favorite weatherproof jacket keeps you dry even in the heaviest of rainstorms? Well, weatherproof enclosures do the same for actuators. These enclosures are designed to resist the onslaught of rain, snow, and dust, keeping your precious actuator dry and protected. They act as a shield against nature’s temper tantrums, ensuring smooth operation no matter what Mother Nature throws at you.

4.2 Explosion-proof Enclosures

We all know that explosions are best left to action movies, not industrial sites. Actuators operating in hazardous environments, like oil refineries or chemical plants, need a little extra TLC (Tender Loving Casing). Explosion-proof enclosures are specifically built to contain and prevent sparks or flames from escaping and igniting hazardous substances. They are like a superhero cape, protecting your actuator and saving the day.

4.3 Hazardous Location Enclosures

Just like a “Do Not Enter” sign warns you of danger ahead, hazardous location enclosures warn potential threats to keep their distance. These enclosures are designed to meet stringent safety standards and regulations for specific hazardous environments. They ensure that your actuator plays it safe in areas where flammable gases, vapors, or combustible dust particles are present. Safety first!

And there you have it, a crash course on enclosures for in-field actuators. Now that you know the importance of these protective shells, go forth and equip your actuators with the enclosures they deserve.

5. Design Considerations for Enclosures

5.1 Proper Ventilation and Heat Dissipation

When it comes to enclosures for in-field actuators, proper ventilation is key. Actuators can generate heat during operation, and if not properly ventilated, they can overheat. So, make sure your enclosure has adequate airflow to keep things cool and running smoothly.

5.2 Cable Entry and Connection Points

Let’s talk about cables, shall we? Actuators need to be connected to various power and control sources, and that means you need to have convenient cable entry and connection points in your enclosure. Otherwise, you’ll end up with a tangled mess of wires that would make even a seasoned electrician shed a tear. So, plan ahead and make sure your cables have an easy way in and out.

5.3 Mounting Options and Accessibility

You know what they say, “Mount it right or suffer the consequences.” Well, maybe they don’t actually say that, but they should. When designing your enclosure, consider the mounting options available and ensure easy accessibility for installation and maintenance. You don’t want to create a situation where someone has to perform a contortionist routine just to change a battery.

6. Installation and Maintenance of Actuator Enclosures

6.1 Proper Installation Techniques

Follow the instructions, use the right tools, and take your time. Don’t rush it like a contestant on a cooking show trying to beat the clock. Trust me, a properly installed enclosure will save you headaches down the road.

6.2 Routine Maintenance and Inspection

Regular inspections can help catch any issues before they become major problems.

7. Future Trends in Actuator Enclosures

7.1 Advancements in Enclosure Materials and Technologies

The world of actuator enclosures is evolving faster than a caterpillar turning into a butterfly. With advancements in materials and technologies, enclosures are becoming lighter, stronger, and more resistant to various environmental conditions. Get ready to say goodbye to clunky metal boxes and hello to sleek and efficient enclosures of the future.

8.2 Integration of IoT and Smart Features in Actuator Enclosures

In the age of smart everything, why should actuators be left behind? Imagine an enclosure that not only protects your actuator but also communicates with you and other systems. From remote monitoring to predictive maintenance, the integration of IoT and smart features in actuator enclosures is poised to revolutionize the way we interact with and manage our equipment.

In conclusion, enclosures for in-field actuators play a vital role in safeguarding these critical components from harsh environments and ensuring their reliability. By considering factors like environmental conditions, size, and material selection, businesses can choose the appropriate enclosure type for their specific needs. Proper design, installation, and maintenance practices further contribute to the longevity and efficient operation of the actuator system. Looking ahead, advancements in enclosure materials, technologies, and integration of smart features hold promising prospects for the future of actuator enclosures. By staying informed about these developments, businesses can stay ahead of the curve and maximize the performance of their in-field actuators. Overall, investing in high-quality enclosures is a wise decision that leads to enhanced productivity, reduced downtime, and increased operational efficiency in various industries.